Accessories

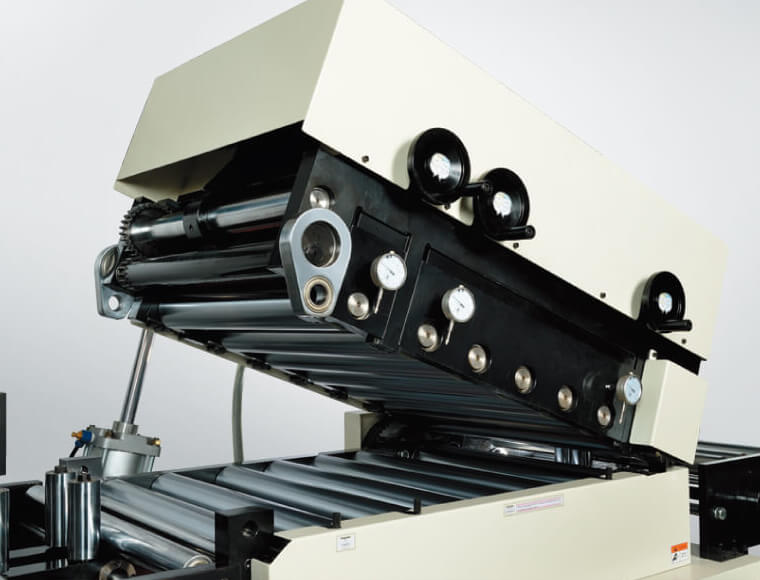

Flip – Top leveler head device.

The opening function is designed for cleaning the working rolls.

Specialty

- Height leveling

- Height efficiency

- Feeding accuracy

- Saving space over 60%

- Height stability

- Height precision

- Standard Accessories:

Flip-Top Leveler Head Device

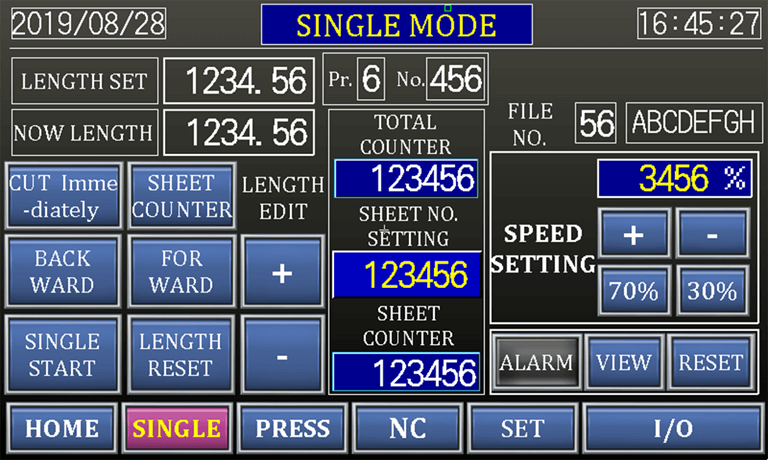

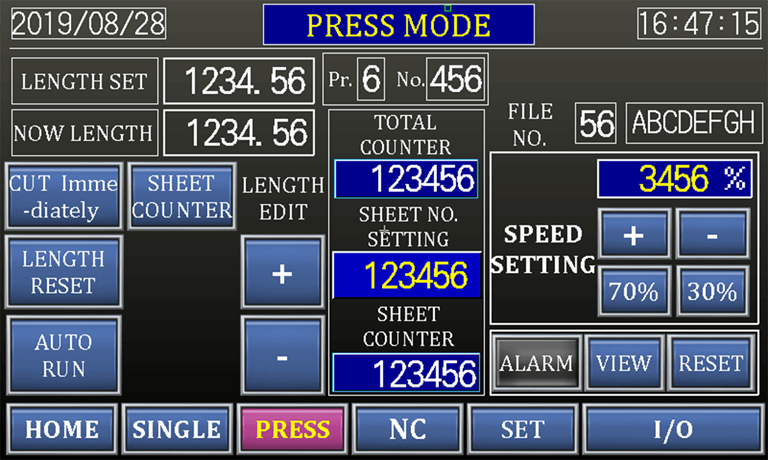

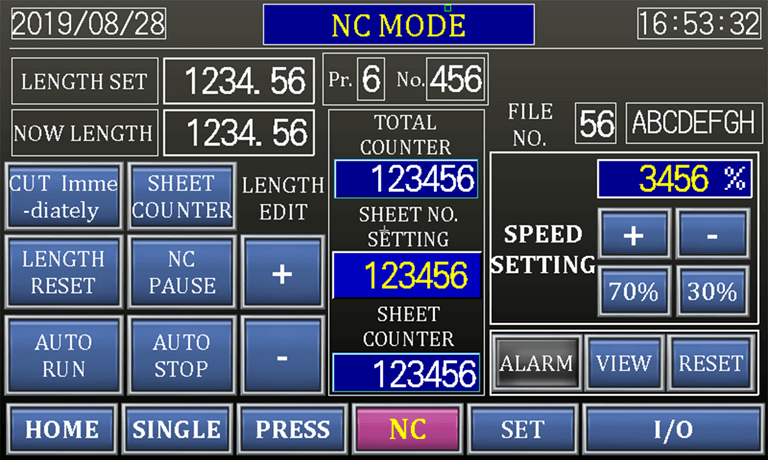

Servo Control System

Main menu : Can choose Chinese and English language menu

Single Mode : For stamting testing run purpose and Single safe mode operation

Press Mode : Continual operation mode under press control

NC Mode : Continual operation mode under feeder control

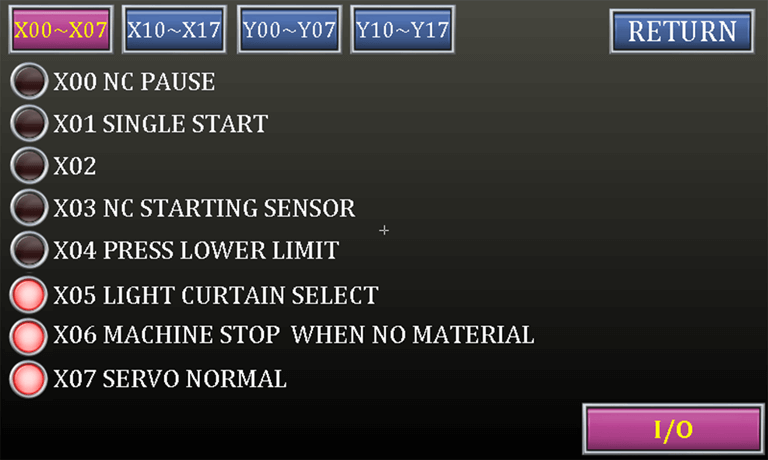

I/0 MONITORING SCREEN

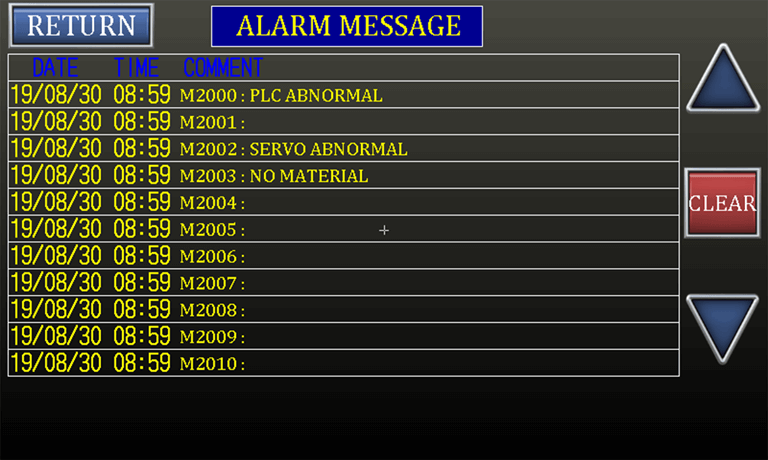

ALARM MESSAGE SCREEN

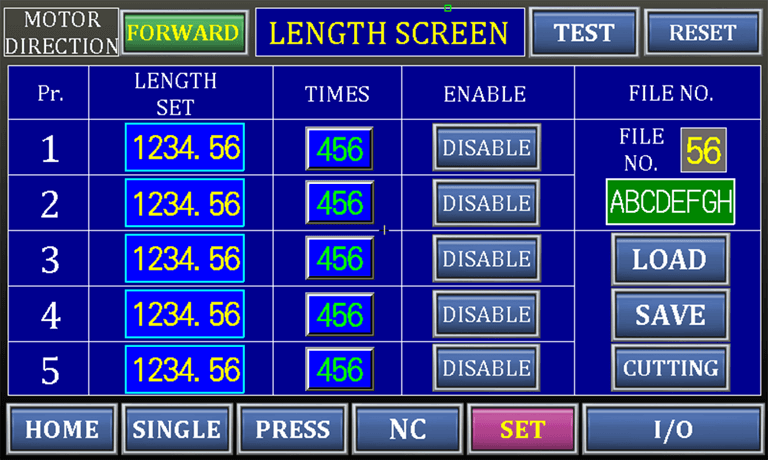

Programmable Multi - Pitch Setting

Material length setting: Applicable for multi-feeding length setting requirment.

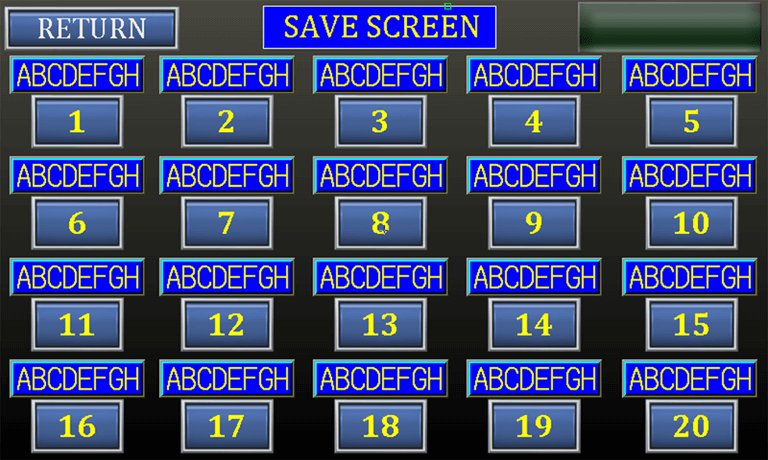

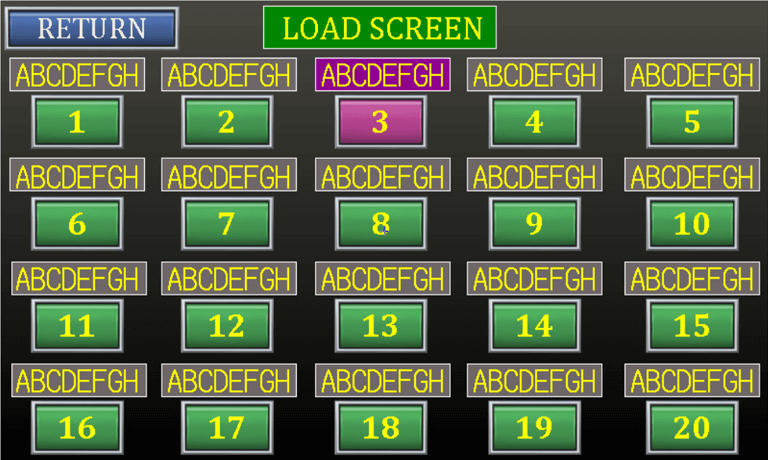

Save Memory Function This function

This function can record feeding length value to save or recall, and it is cooperation with dies number to record memory.

Leveler Rolls

- New concept and design reduces space requirements.

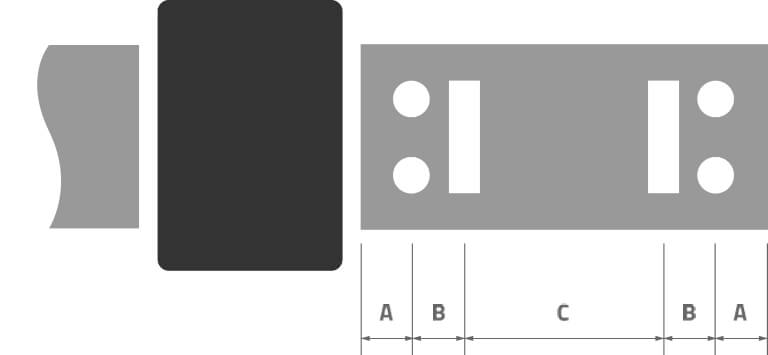

- The unique 2 sections leveling design for solving the high flatness and leveling stability of material requirement.

- Flip – Top leveler head device for easy maintenance operation.

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control system.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

- Feeder rolls and straightener rolls have undergone special heat treatment of HRC 60° for high precision leveling, rolls surface chromium-plating and then ground, high hardness, high wear-resistant characteristic and long service life cycle.

- Uncoiler hydraulic expansion design makes the job more efficiently.

- Collocation twin type uncoiler and coil car, save loading coil time increase efficiency.

NCT1 Series + Uncoiler

Specifications

NCT1 Series

| Modle | NCT1-300 | NCT1-400 | NCT1-500 | NCT1-600 | NCT1-700 | NCT1-800 | NCT1-900 | NCT1-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 0.3 ~ 1.0 | |||||||

| Feed Roll (mm) | 70 x 2 pcs | |||||||

| Work Roll (mm) | 40 x 12 pcs | 40 x 12 pcs | 40 x 12 pcs | 40 x 12 pcs | 50 x 12 pcs | 50 x 12 pcs | 50 x 12 pcs | 50 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 2.0 | 3.5 | 3.5 | 3.5 | 5.0 | 5.0 | 5.0 | 7.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 |

NCT2 Series + Uncoiler

Specifications

NCT2 Series

| Modle | NCT2-300 | NCT2-400 | NCT2-500 | NCT2-600 | NCT2-700 | NCT2-800 | NCT2-900 | NCT2-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 0.4 ~ 2.0 | |||||||

| Feed Roll (mm) | 70 x 2 pcs | 96 x 2 pcs | 132 x 2 pcs | |||||

| Work Roll (mm) | 50 x 12 pcs | 50 x 12 pcs | 50 x 12 pcs | 60 x 12 pcs | 60 x 12 pcs | 60 x 12 pcs | 60 x 12 pcs | 72 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 2.0 | 3.5 | 3.5 | 3.5 | 5.0 | 5.0 | 5.0 | 7.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 |

NCT3 Series + Uncoiler

Specifications

NCT3 Series

| Modle | NCT3-300 | NCT3-400 | NCT3-500 | NCT3-600 | NCT3-700 | NCT3-800 | NCT3-900 | NCT3-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 0.5 ~ 3.0 | |||||||

| Feed Roll (mm) | 96 x 2 pcs | 112 x 2 pcs | 132 x 2 pcs | |||||

| Work Roll (mm) | 60 x 12 pcs | 60 x 12 pcs | 60 x 12 pcs | 72 x 12 pcs | 72 x 12 pcs | 72 x 12 pcs | 84 x 12 pcs | 84 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 3.5 | 5.0 | 5.0 | 5.0 | 7.0 | 7.0 | 7.0 | 11.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 |

NCT4 Series + Uncoiler

Specifications

NCT4 Series

| Modle | NCT4-300 | NCT4-400 | NCT4-500 | NCT4-600 | NCT4-700 | NCT4-800 | NCT4-900 | NCT4-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 0.8 ~ 4.0 | |||||||

| Feed Roll (mm) | 112 x 2 pcs | 132 x 2 pcs | ||||||

| Work Roll (mm) | 72 x 12 pcs | 72 x 12 pcs | 72 x 12 pcs | 84 x 12 pcs | 84 x 12 pcs | 84 x 12 pcs | 96 x 12 pcs | 96 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 3.5 | 5.0 | 5.0 | 5.0 | 7.0 | 7.0 | 7.0 | 11.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 2 | 2 | 3 | 3 | 5 | 5 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 |

NCT5 Series + Uncoiler

Specifications

NCT5 Series

| Modle | NCT5-300 | NCT5-400 | NCT5-500 | NCT5-600 | NCT5-700 | NCT5-800 | NCT5-900 | NCT5-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 1.0 ~ 5.0 | |||||||

| Feed Roll (mm) | 114 x 2 pcs | 132 x 2 pcs | ||||||

| Work Roll (mm) | 84 x 12 pcs | 84 x 12 pcs | 84 x 12 pcs | 96 x 12 pcs | 96 x 12 pcs | 96 x 12 pcs | 114 x 12 pcs | 114 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 5.0 | 5.0 | 5.0 | 7.0 | 7.0 | 7.0 | 11.0 | 11.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 2 | 2 | 3 | 3 | 5 | 5 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 |

NCT6 Series + Uncoiler

Specifications

NCT6 Series

| Modle | NCT6-300 | NCT6-400 | NCT6-500 | NCT6-600 | NCT6-700 | NCT6-800 | NCT6-900 | NCT6-1000 |

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Thickness of Material (mm) | 1.0 ~ 6.0 | |||||||

| Feed Roll (mm) | 114 x 2 pcs | 132 x 2 pcs | 144 x 2 pcs | |||||

| Work Roll (mm) | 96 x 12 pcs | 96 x 12 pcs | 96 x 12 pcs | 114 x 12 pcs | 114 x 12 pcs | 114 x 12 pcs | 120 x 12 pcs | 120 x 12 pcs |

| Work Roll Arrangement | First Section:Upper 1 / Lower 2, Second Section:Upper 5 / Lower 4 | |||||||

| Main Servo Motor (kW) | 5.0 | 5.0 | 7.0 | 7.0 | 7.0 | 11.0 | 15.0 | 15.0 |

| Air Supply (kg/cm2) | 5 | |||||||

| P.L.H Adjustment (mm) | Cust. Demand High ±100 | |||||||

Uncoiler

| Width of Material (mm) | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max. Coil Weight (kg) | 1500 | 2000 | 2000 | 3000 | 3000 | 5000 | 5000 | 5000 |

| Coil I.D. (mm) | Ø450 ~ 520 | Ø480 ~ 520 | ||||||

| Max. Coil O.D. (mm) | 1200 or 1500 | |||||||

| Uncoiler Expansion | Hydraulic | |||||||

| Uncoiler Motor (HP) | 1 | 2 | 2 | 3 | 3 | 5 | 5 | 5 |

| Uncoiler Inverter (kW) | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 |

Standard Accessories

- Programmable multi – pitch setting with cutting signal output function. (Cutting signal output function is able to control the cutting device.)

- HMI touch screen control panel.

- 2 points micro adjustment (Attached with dial gauge)

- Flip – Top leveler head device.

- Leveler work rolls air release.

- Motor drive uncoiler with inverter control.

- Uncoiler photoelectric sensor control unit.

- Uncoiler hydraulic mandrel expansion device.

- Manual coil guide.

- Snubber arm.

- Carry over guide.

- Carry over clamp. (Applicable to NCT4 above)

- Peeler.

- Pre – bender. (Applicable to NCT4 above)

Optional Accessories

- Coil car (Coil loading assisting device).

- Motorized pass line high adjustment device.