Specialty

- Air release

- Feeding accuracy

- Height stability

- Customer demand

- Special software program demand

Servo Control System

Main menu : Can choose Chinese and English language menu

Single Mode : For stamting testing run purpose and Single safe mode operation

Press Mode : Continual operation mode under press control

NC Mode : Continual operation mode under feeder control

I/0 Monitoring Screen

Alarm Message Screen

Programmable Multi - Pitch Setting

Material length setting: Applicable for multi-feeding length setting requirment.

Save Memory Function

This function can record feeding length value to save or recall, and it is cooperation with dies number to record memory.

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control.

- Programmable multi-pitch setting function to support the different feeding length and feeding frequency requirement.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

- Applicable for selecting the optional 4 feeding rolls to meet the thicker material request, to ensure the feeding accuracy.

NC Series + Uncoiler

Specifications

NC Series

| Modle | NC-150 | NC-200 | NC-300 | NC-300S | NC-400 | NC-500 | NC-600 | NC-800 | NC-1000 | NC-1250 |

| Width of Material (mm) | 150 | 200 | 300 | 300 | 400 | 500 | 600 | 800 | 1000 | 1250 |

| Thickness of Material (mm) | 0.1 ~ 2.0 | 0.1 ~ 3.0 (Option:4 or 6) | ||||||||

| Feed Roll Up (mm) | 72 x 1 (Pu Roll) | 112 x 1 (Pu Roll) | ||||||||

| Work Roll Down (mm) | 72 x 1 | 112 x 1 | ||||||||

| Servo Motor (kW) | 1.0 | 1.0 | 1.0 | 2.0 | 2.0 | 3.5 | 3.5 | 5.0 | 5.0 | 7.0 |

| Feed Length (mm) | 1~ 9999.99 | |||||||||

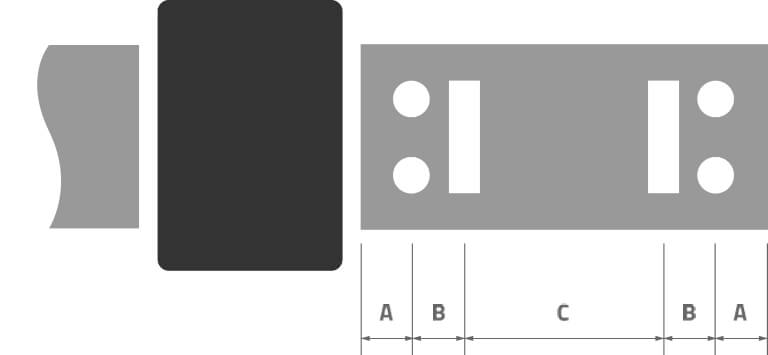

| P.L.H Adjustment (mm) | 156~226 | 187~367 | ||||||||

Standard Accessories

- Programmable multi-pitch setting with cutting signal output function.

(Cutting signal output function is able to control the cutting device.) - 5.7 “Mitsubishi Touch panel

- PLC controller - Mitsubishi (Made in Japan)

- NC servo controller - Mitsubishi (Made in Japan)

- Feeding rolls air release.

Optional Accessories

- Micro-Adjusted lubricator

- Gear box driven type device.

((Applicable to material thickness above 3 ~ 4 mm) - Four feeding rolls set unit with gear box driving device.

(Applicable to material thickness above 5 ~ 6 mm)

- Closed loop type AC servo control system.

- Special software demand.