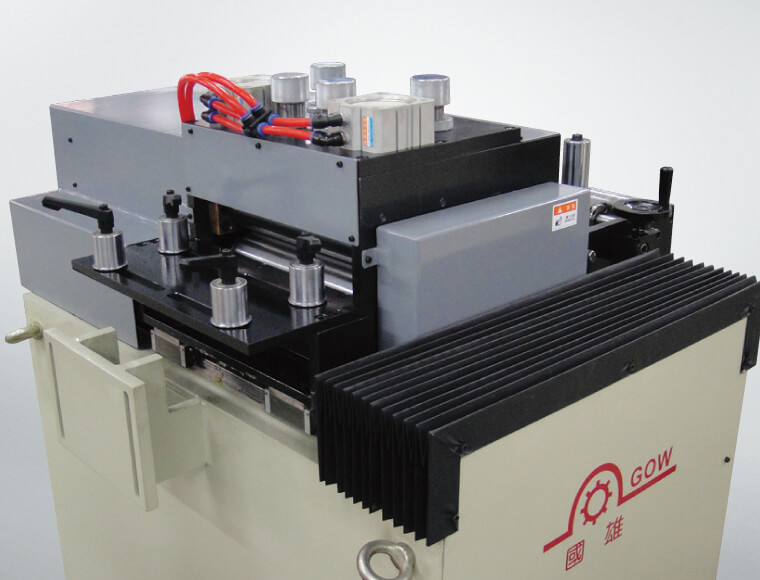

Part Photo

Specialty

- Air release

- Material cost saving

- Height stability

- Special software program demand

- High efficiency

- Feeding accuracy

- Customer demand

Action method

Servo Control System

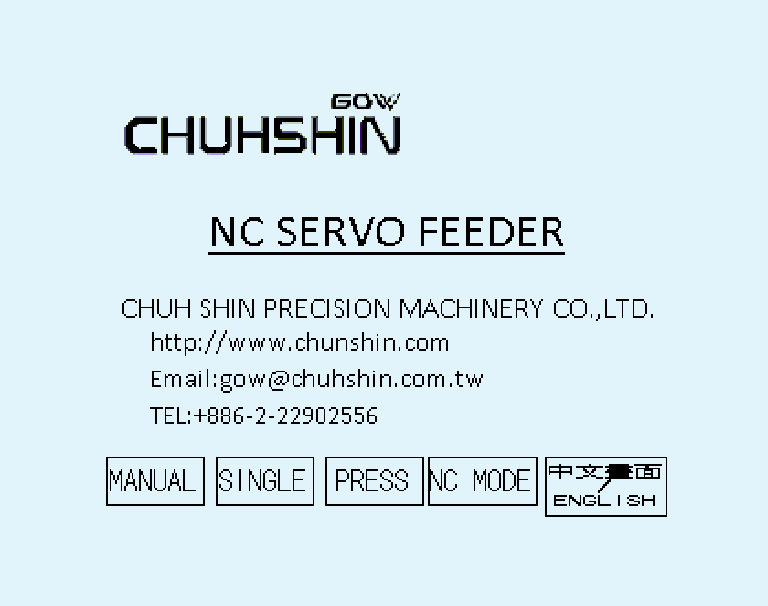

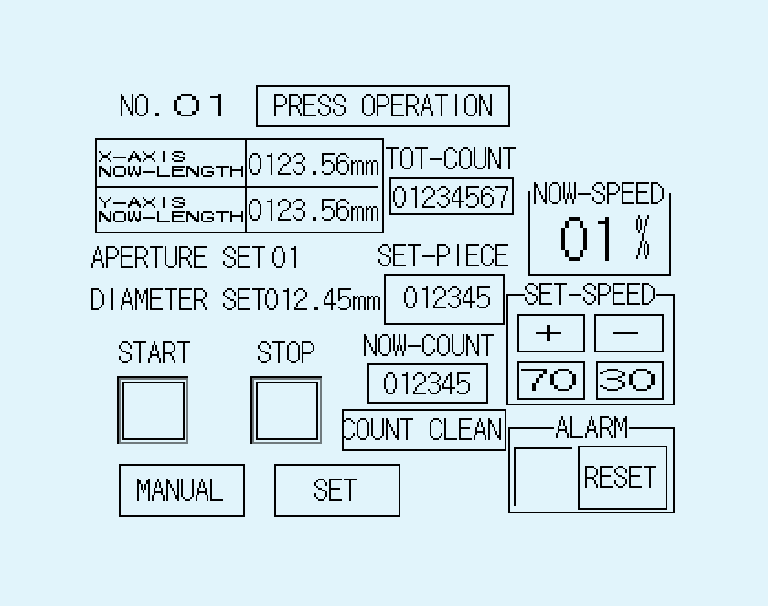

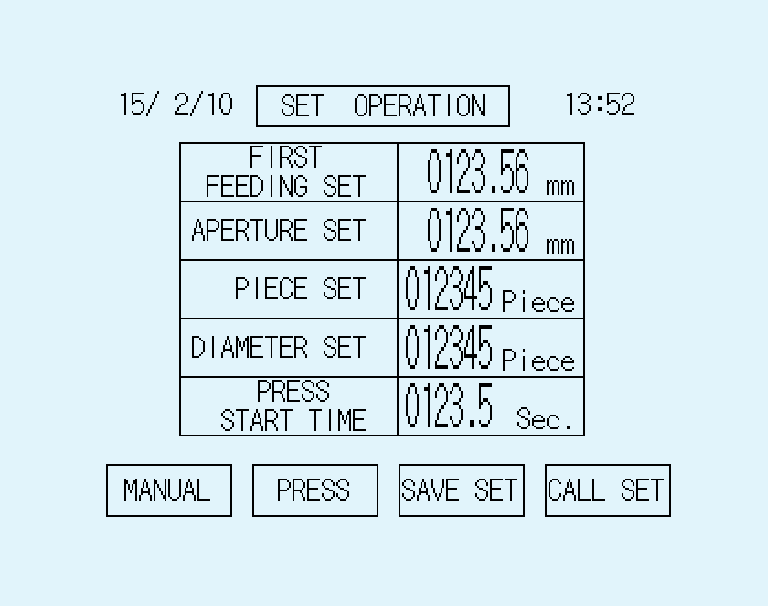

Main menu:Can choose Chinese and English language menu.

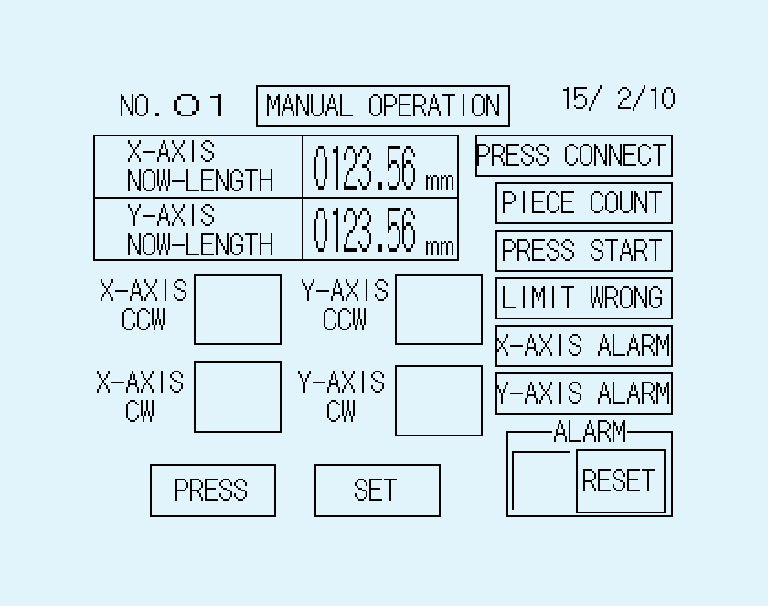

Manual Mode:For stamting testing run purpose

Press Mode:Continual operation mode under press control

Material length setting

- High rigidity mechanical structure design and work with Mitsubishi servo control system to ensure the feeding accuracy.

- Friendly operation by adopting Human Machine Interface control.

- Programmable multi-pitch setting function to support the different feeding length and feeding frequency requirement.

- Auto feed monitoring function which can be a safety operation when the unit interlock with press stamping operation.

- Applicable for selecting the optional 4 feeding rolls to meet the thicker material request, to ensure the feeding accuracy.

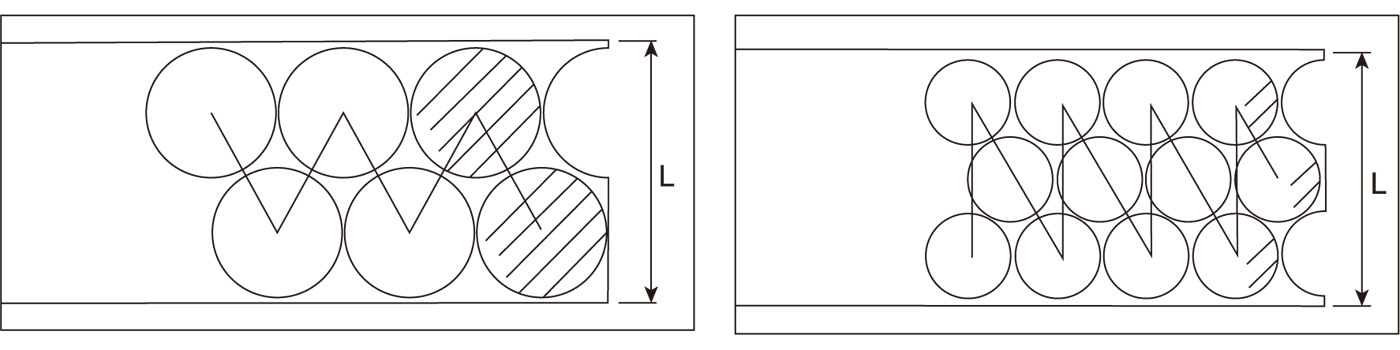

- Zig – Zag motion feeding feature is to achieve the material cost saving and that is performing better than the conventional feeders.

- The unit is made under the one-piece body construction design and adopting the linear slide rails, ball screw driving device to achieve the highest working stability.

NC–RL Zig–Zag Series + Uncoiler

Specifications

NC–RL Zig–Zag Series

| Modle | NC-200RL | NC-300RL | NC-400RL | NC-500RL | NC-600RL |

| Width of Material (mm) | 200 | 300 | 400 | 500 | 600 |

| Thickness of Material (mm) | 0.1 ~ 3.0 (Option: 4 or 6) | ||||

| Feed Roll Up (mm) | 112 x 1 (Pu Roll) | ||||

| Work Roll Down (mm) | 112 x 1 | ||||

| Servo Motor (kW) | 2 | 2 | 3.5 | 5.0 | 5.0 |

| Speed (spm) | 0 ~ 9999.99 | ||||

All Specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.

Standard Accessories

- 5.7 “Mitsubishi Touch panel

- Zig-Zag motion controlled by servo motor system; Linear slide rails/2 pieces; Boll screw/1 piece. Programmable for 5 rows movement control.

- PLC controller - Mitsubishi (Made in Japan)

- NC servo controller - Mitsubishi (Made in Japan)

- Feeding rolls air release

Optional Accessories

- Micro-Adjusted lubricator

- Gear box driven type device.

(Applicable to material thickness above 3 ~ 4 mm)

- Special software demand.

- Four feeding rolls set unit with gear box driving device.

(Applicable to material thickness above 5 ~ 6 mm)